Industry 4.0, or the Fourth Industrial Revolution, is set to revolutionise the manufacturing and production industry by integrating the Internet of Things (IoT), cloud computing, data integration and other technological advances into the heart of production and manufacturing systems.

There are lots of elements that go into the concept of Industry 4.0, so we’ve broken down some of the key concepts, as well as what it is, where it came from, and what it means for the manufacturing sector.

What is Industry 4.0?

Industry 4.0 is the next revolution in industrialisation. The premise is to take all the individual processes and computing that factory machines perform in their siloed systems and import them into the cloud, meaning the workflow, upkeep, and management of each individual machine and series of machines can be done remotely.

To understand how this works, you need to understand two concepts: cloud computing and the internet of things (IoT). Cloud computing is hosted on the internet and allows for remote access to apps, services, and stored data. The internet of things builds on this concept by using the cloud to store and automate processes in objects that are synced to the internet, like internet-enabled automobiles and remote home lighting and shade systems. Industry 4.0 utilises both cloud computing and the internet of things to take processes that are normally managed internally by both people and machines and move them into the cloud where they can be managed from anywhere in the world.

The Fourth Industrial Revolution challenges the traditional way that manufacturing and production systems in factories currently function, with centralised and offline systems that are not inter-connected. The prediction is that these factories will soon evolve into “smart factories” with the capability to self-manage issues and internal processes. In turn, manufacturing execution systems (MES) that determine how factories run and function will have to evolve with these concepts in mind or get left behind.

The History of Industry 4.0

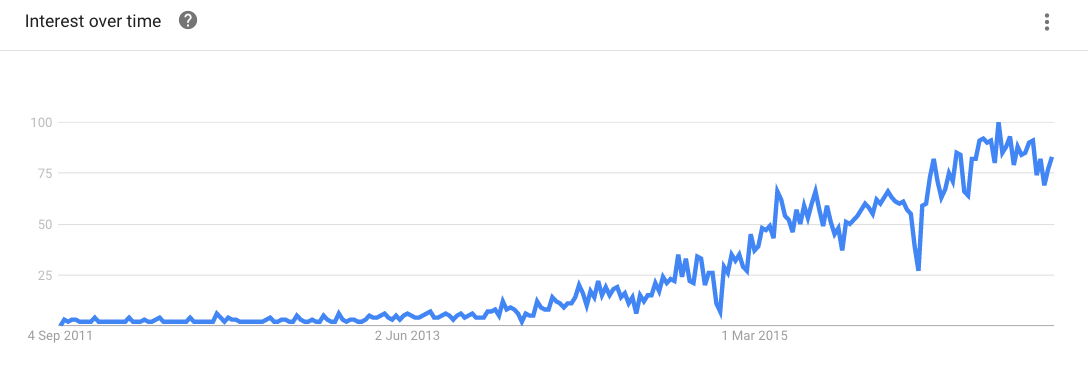

Though industry experts disagree on how quickly this evolution will occur, Industry 4.0 has been seeping into the manufacturing sector since 2011. Coined in Germany at the world’s biggest industrial fair, Hannover Messe, it has since emerged as a concept that has not only set the wheels in motion to leverage Germany’s engineering and manufacturing prowess, but that will take the rest of the world’s manufacturers along with it.

Since that first announcement, Industry 4.0 has started to disrupt the manufacturing industry. There’s a reason Industry 4.0 has been heralded as the Fourth Industrial Revolution — it has the same potential to disrupt the industry the other three industrial revolutions had during the Victorian era with mechanisation, in the early 1900’s with assembly lines, and in the mid to late 1900’s when computers first appeared on the factory floor.

Unlike the revolutions of the past, however, this one has been a long time coming, allowing for manufacturers and systems time to get ahead before it hits. Still, Germany continues to lead the way in developing the thought leadership of Industry 4.0, with a significant amount more research, search queries and coverage from the German sector than in all the English-speaking divisions combined.

Industry 4.0 and the Industrial Internet of Things

We can think of cloud computing and the internet of things as the springboard that has brought Industry 4.0 to the forefront of our factories. That’s why some have also come to call it the “Industrial Internet of Things”. Outside of factories, these “things” are called Cyber-Physical Systems (CPS): physical objects with embedded software and computing power, like the navigation system in your car or the activity tracker on your wrist.

Within a manufacturing system, these “things” become more complex and are called Cyber-Physical Production Systems (CPPS). CPPS are software-enhanced machinery that not only have computing power like typical IoT objects, but also have embedded sensors and actuators designed to self-diagnose and make decisions based on their current state.

As explained in the Journal of Innovation Management, “a smart resource or CPPS will know its state, its history, its maintenance plan, its capacity, its range of possible configurations and setups, etc.” This is the big difference: CPS work independently to communicate and store information in the cloud, where CPPS work to form a self-maintaining, self-diagnosing network in the cloud.

The Journal of Innovation Management has published research on the revolution and future of these Manufacturing Execution Systems (MES) that found that for Industry 4.0 to take effect, multiple “technology enablers” such as 3D printing, mobile devices and big data, among others need to work together to create a new working system. The manufacturing systems of the future, including MES, will have to be built to support this paradigm shift.

Challenges of Industry 4.0

The challenges of Industry 4.0 are immense. Not only will this enhanced system require a complete upheaval of the way factories currently work, it will also change the way suppliers, workers, engineers, and analysts work as well. Off the back of a new report from business advisory firm BDO, Business Weekly estimates that while UK manufacturers recognise Industry 4.0’s importance, “only eight per cent of UK manufacturers have a significant understanding of the processes involved despite 59 per cent recognising that a fourth industrial revolution would have a big impact on the sector.” A lack of education can result in a lack of investment.

Beyond education, not all businesses can afford to completely revolutionise or overhaul their systems. Some factories still haven’t caught up with the last industrial revolution, so they should be focusing their energy on practical and incremental approaches to improve things like their efficiency and product quality. Those that are somewhere in-between will need to be able to bridge the gap by marrying the technology they already have with what’s coming.

And what’s coming isn’t just machines that think in the cloud, there’s also going to be mountains of new data. This is a challenge that non-industrial businesses are already facing—what do we do with the piles of data we’ve collected and how do we prioritise the important parts? Now, it will be a question for those implementing the Industrial Internet of Things as well.

Advantages of Industry 4.0

Still, amidst all these challenges, the benefits and idealism of Industry 4.0 prevail. From productivity to customer personalisation, it’s hard to deny that those who are scared away by the challenges are also fleeing from the potential overcoming these challenges brings.

The most obvious advantage is increased productivity and profitability. In a late 2014 survey from PWC, companies who are actively implementing measures to implement Industry 4.0 solutions expected more than 18% higher productivity over the next five years. With higher demands on the industrial sector to produce more materials with fewer raw materials and less energy, implementing decentralised systems that promote efficiency, flexibility, and are more sustainable is a must. Integration of smart materials and equipment that can diagnose and fix itself will help streamline processes, make more versatile production decisions, and invariably increase profitability.

Customers will benefit as well. We already know that automating productions can improve quality, consistency and reliability, but there has always been a cost associated with personalisation. Now, made-to order or customisable products can be more easily created and for lower cost, no matter if a company prints personalised t-shirts or customises prosthetic legs with a 3D printer. If a process can be customised based on the product it’s producing, variants in the products should be much easier to accommodate.

Lastly, remember all that challenging data? It can draw huge benefits if managed correctly. In that same PWC study, 90% of companies said they believe that the ability to analyse data will be decisive to their business model in five years. This can be used to further optimise productivity, analyse the effectiveness of products, regulate the types of products being produced, and more. The fear of too much data dissolves with data lakes and big data processing, leading to data reporting and analytics.

Industry 4.0’s Impact and Where We Are Today

Even though some UK businesses have said they are struggling to keep up with the expectations set in other manufacturing realms, other reports state that by 2020, European industrial companies will invest €140 billion annually in Industrial Internet applications, which is encouraging.

We’re seeing this at Salesforce within our own customers’ successes. Beth Comstock, GE’s CMO asked herself, “If my jet engine could talk to me, what would it say?”. With the implementation of GE’s data feed from a GE NX engine, now she knows. They used an engine’s data feed from a dreamliner for Japan Airlines to diagnose potential issues, then sent this data on to engineers. Though it wasn’t able to repair itself, this is a classic example of how the Industrial Internet of Things can translate mechanical issues into human action.

For every business that is considering a digital transformation in manufacturing, there is another that simply refuses to acknowledge Industry 4.0 is happening. Meanwhile, Salesforce provides key capabilities to succeed in the Industry 4.0 age with it’s customer success platform.

The Fourth Industrial Revolution won’t swoop into our operations and factories overnight, this is certain, but the technology that has elevated industries once again isn’t going anywhere but up. It’s critical that manufacturers begin building their digital transformation roadmap today before they get left behind.

A great place for manufacturers to begin their digital transformation is with their sales organisation. Download our e-book to read more about how Salesforce solutions can help manufacturing companies to differentiate and assist their front line sales teams compete in this new landscape.